Welcome to the

Elopak online design guide

The series of instructions and explanations presented in this web-site are meant to facilitate your design process, maximize your output and help you to utilize the many aspects of our printing process. Artwork prepared in accordance with the Elopak requirements secures production output consistent with the highest industry standards.

By using examples and definitions, we will guide you through the benefits and capabilities of the Elopak printing process.

Environmentally friendly printing

Elopak offers a standardized, environmentally friendly printing process – flexo and litho. We aim to provide high-quality service every step of the way and we are continually developing our expertise to match the highest market requirements.

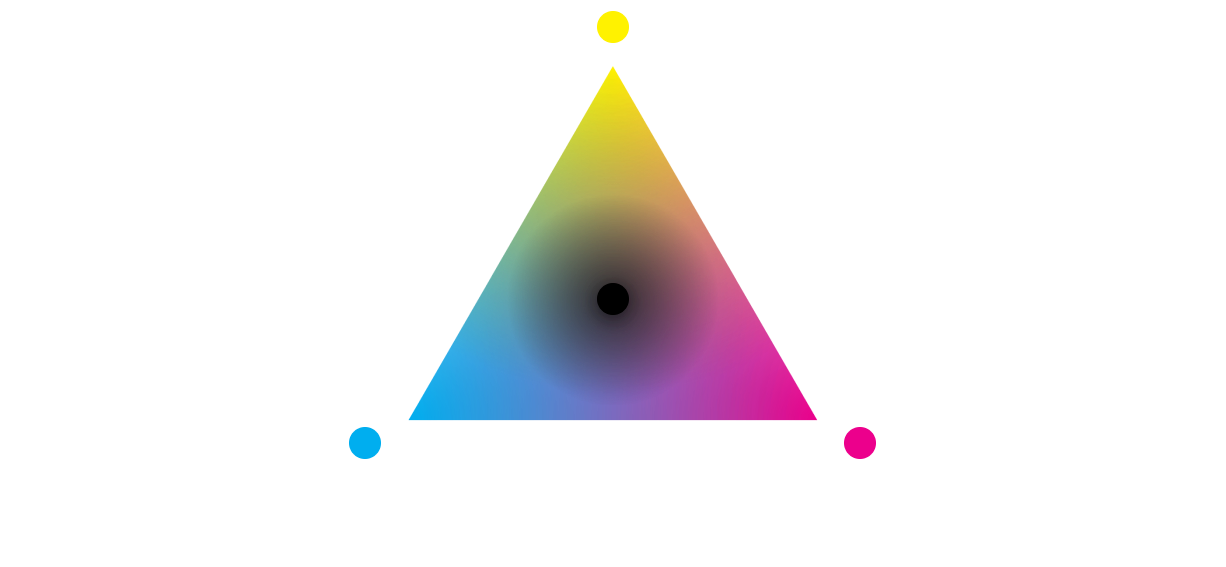

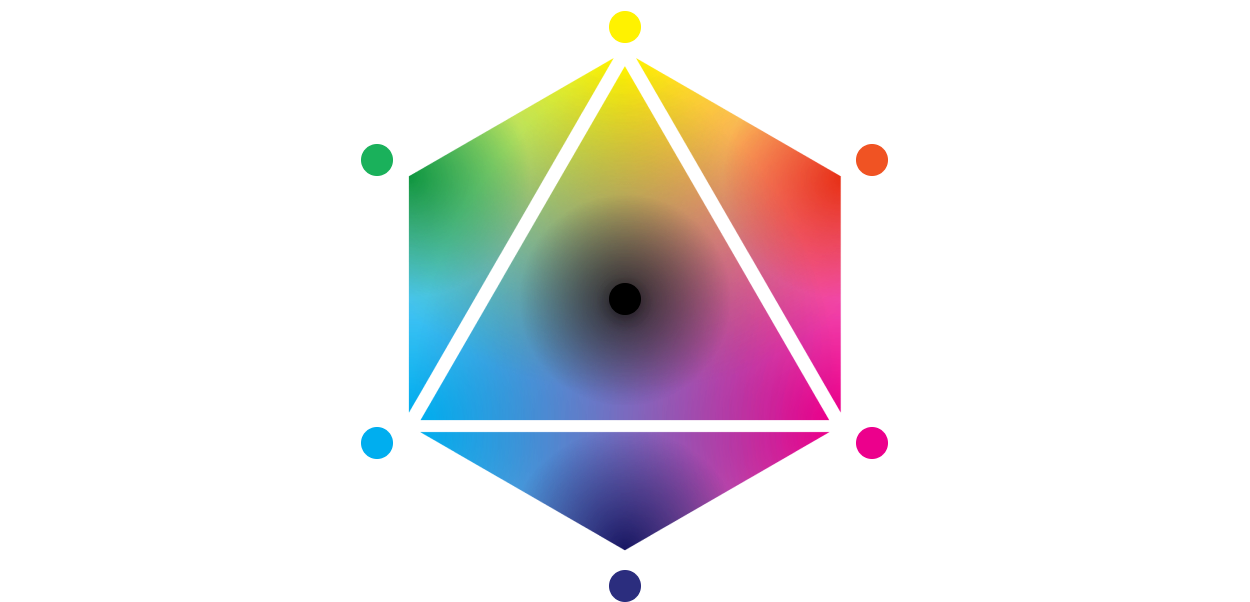

Superior color gamut

Elopak uses a fully standardized multi-color printing ink setup named EloChrome.

This on-press color mixing system consists of CMYK process inks

Cyan

Magenta

Yellow

Black

supported by 4 additional special inks.

Plus

EloViolet

EloGrey

EloOrange

EloGreen

These EloChrome inks are fixed and cannot be substituted with other spot colors.

System setup varies from process to process. For Elopak flexo EloGreen is not available. For Elopak litho EloGrey is not available.

CMYK

EloChrome

Pure inks and color build-ups

Each of the 8 EloChrome inks is referred to as a “single color”.

A composite color achieved by mixing 2 or 3 pure inks is referred to as a “color build-up”.

Cyan

Magenta

Yellow

Black

EloViolet

EloOrange

EloGrey

EloGreen

Aa

Pure ink single colors allow for finer details and thinner lines.

Aa

Composite color build-ups require additional thickness for the application of trapping, to ensure optimal quality, production stability and robustness.

Repro operations hub organization

Repro Operations Hub is a department within Elopak which handles the coordination of all the prepress work. It is responsible for artwork evaluation, preproduction, proofing, planning and customer communication. This team of industry professionals consists of design managers, DTP-operators and quality checkers, all working closely together.

Every artwork supplied to Elopak Repro Operations Hub makes the same journey:

Artwork Delivery

A customer or a design agency supplies artwork to Elopak, which is then forwarded to the Repro Operations Hub. It is received by the responsible Design Manager.

Incoming Check

Delivered artwork is thoroughly checked against Elopak requirements, to make sure the printing will result in the best quality possible.

Artwork Feedback

Incoming check feedback is provided to the design agency and/or customer. The artwork can either be accepted or rejected. The Repro Hub can do small modifications to meet the production demands. This is always communicated as soon as possible.

Artwork to Prepress Specialist

When the artwork is part of a range of products, this will be specified to ensure similar elements (e.g. logos) will be treated in the same way. All artworks will be forwarded to our prepress specialists. They have the responsibility to ensure that delivered artwork fulfills the customer expectations while also meeting Elopak production demands and securing optimal and consistent quality.

Color Matching

The prepress specialists convert e.g. Pantone colors to EloChrome. Images are optimized. Supplied color targets or Pantone reference colors are matched.

Output Check

Our process quality experts check the prepress output before soft/hard proofs can be delivered to the customer.

PakTrack

The processed design is uploaded in our web-based design progression and collaboration tool, PakTrack, in the form of a PDF soft proof. All relevant parties involved are automatically notified that the design is available for review.

PDF Soft Proof

A soft proof is an electronic version of the print-ready artwork, specifically adjusted for the Elopak printing process. It is primarily used for text and layout approval, before proceeding with hard proofs for color review.

EloDot proof

A digital hard proof is made – this is called the EloDot. This standardized digital proof is produced using special paper and inks in order to simulate the characteristics of the printing process. This proof is then sent out to the customer and/or the design agency.

Digital Proof Feedback

Customer and/or the design agency gives feedback based on the delivered EloDot proof. (Please note that no visual adjustments can be made on the printing press, meaning that the Elodot proof would need to be customer approved, without comments, before the release of production.)

Final Approval

After receiving the final approval, the artwork is submitted for a preproduction check by our final-check controller. They will make sure that all approved designs are available to the production plant no later than 48 hours post approval

Artwork Delivery

A customer or a design agency supplies artwork to Elopak, which is then forwarded to the Repro Operations Hub. It is received by the responsible Design Manager.

Elopak PrePress

Steps to excellence

Why repro work is necessary

Reprographic work is meant to turn a designer’s idea into real-life printed packaging material through a specific chain of processes. To that end, Elopak operates a dedicated Repro department that evaluates and adjusts customers’ digital files so that the artwork is compatible with EloChrome printing. Images are optimized, colors are converted and matched, trapping and other process-specific requirements are implemented, so that every design is produced to optimal quality and print robustness.

Design requirements

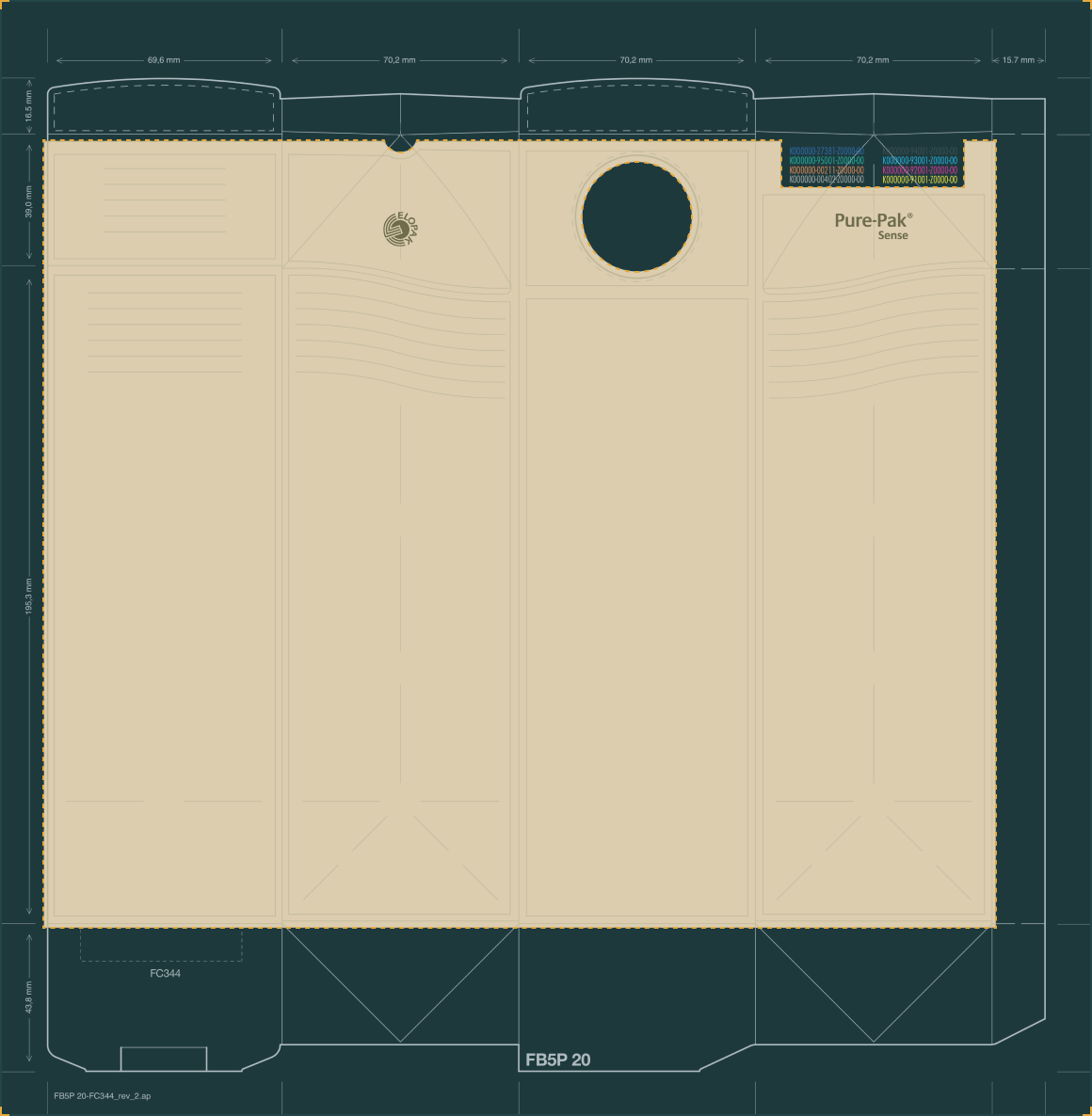

Elopak grids

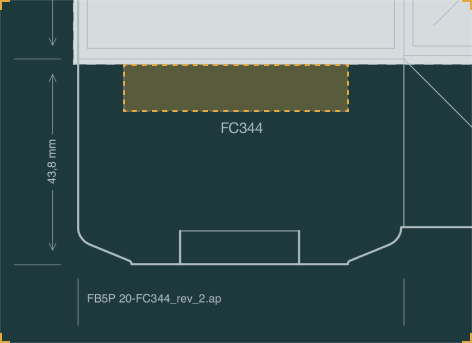

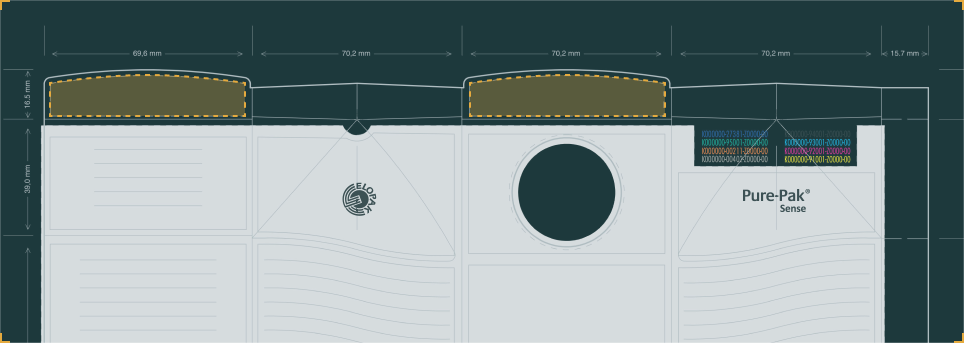

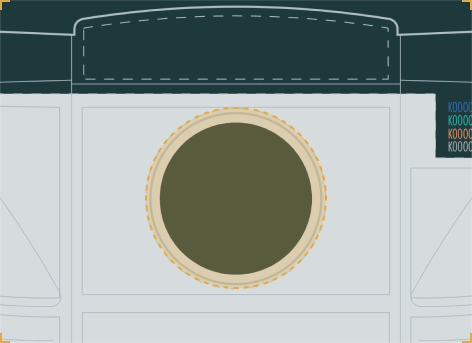

Whenever new artwork is supplied, please make sure to request the appropriate grid/keyline from Elopak personnel. All designs must be delivered on a correct Elopak grid.

In order to facilitate artwork application, the clipping area is tinted and only this area should be used for the layout (as illustrated below).

It is not allowed to alter or modify Elopak grids in any way, as they are size-accurate technical drawings of actual die tools.

Areas of special attention

The bottom area marked with a dotted line may be used for article numbers, food-safe logos or a bottom bar code in a single printing color.

Safe zones need to be strictly adhered to.

The top fins are reserved for minimum print only (e.g. best before info, opening arrows).

If there is a cap closure on the blank, please keep all text and design elements outside the cap safe zone.

This area is marked with dotted lines.

label

FSC

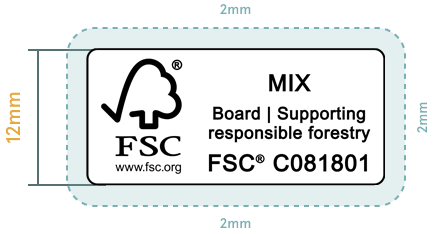

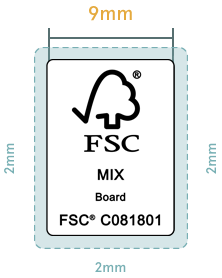

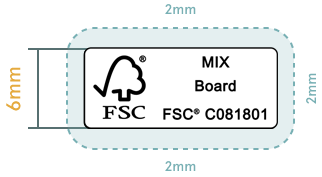

The FSC label can be applied on FSC certified boards. Placement needs to strictly follow FSC guidelines for size and clear area. The label is printed using the darkest single solid color available in the design and needs to have a clear area of 2 mm all around, in all instances.

The FSC label is available in most languages. The label can be placed as either landscape or portrait and comes in two sizes.

Standard size

logos

1L and more

Mini size

logos

0.5L and less

For best results, the use of black text on a white background is recommended. If there are no unprinted/white areas available, the label components may be printed in black or white on a background color with sufficient contrast.

The background should always be a solid color or a soft pattern. If the background is either patterned or an image, the label must be placed on a semi-transparent rounded rectangle. Placement of the label on the bottom of the carton is not allowed.

For more on FSC guidelines, please consult the official Forestry Stewardship Council presentation.

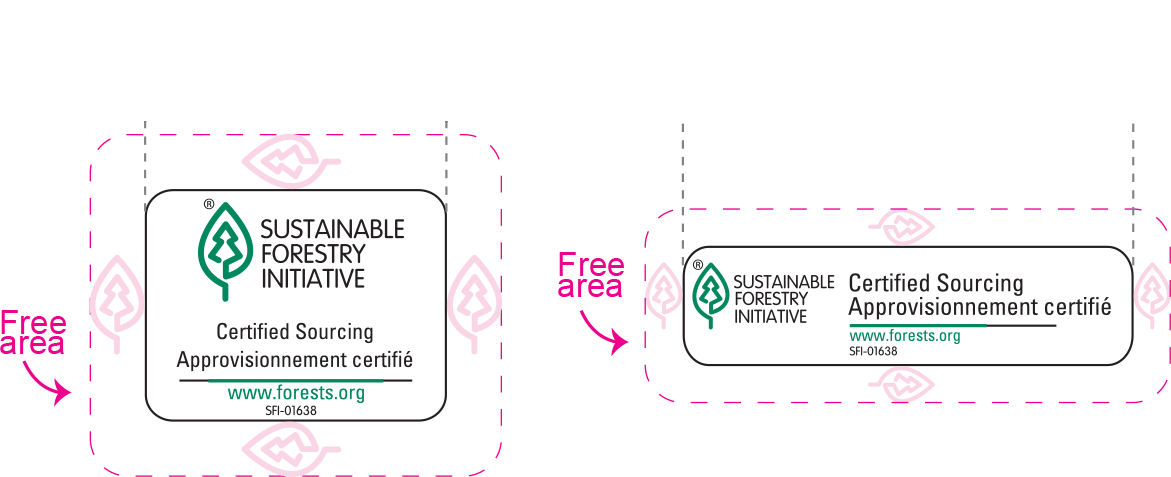

SFI

The SFI label can be applied on SFI certified boards. Placement needs to strictly follow SFI guidelines for size and clear area.

The color of the logo is regulated by SFI. However, the use of the logo in black only is also accepted. To maintain clean, uncluttered layouts and to maximize the impact and recognition of the marks, always maintain an area of isolation all around the logo. The SFI logo is available in French and in English. The logo can be placed as either landscape or portrait

Placement of the label on the bottom of the carton is not allowed.

For more on SFI guidelines, please consult the sfidatabase.org

EloDot proofs

Elopak offers a standardized digital proof, named the EloDot. This proof simulates the characteristics of the printing process. The EloDot will be used for measurementSee more and visual comparison during the printing process.